Overmolding is a process that involves molding one material over another to create a single finished product. This process is extensively used in the manufacturing of products such as electrical connectors, automotive components, medical devices, and more. Overmolding provides a number of benefits, including increased durability, improved grip, and enhanced aesthetics. In this article, we will discuss the most commonly used over-molding materials and their properties, as well as their applications and advantages. If you are a mould manufacturer in India or work with Dowell Moulds, read on to discover the best materials for your next project.

Table of Contents

1. Introduction

2. What is overmolding?

3. Types of Overmolding Materials

- Thermoplastic Elastomers (TPE)

- Thermoplastic Polyurethane (TPU)

- Silicone Rubber

- Polypropylene (PP)

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

4. Applications of Overmolding Materials

5. Advantages of Overmolding

6. Choosing the Right Overmolding Material

7. Overmolding with Dowell Moulds

8. Conclusion

9. FAQs

1. Introduction

Overmolding is a popular process used in the manufacturing industry to create a single product that is made up of two or more materials. This process has gained popularity due to its ability to improve the aesthetics and functionality of a product. The process involves molding one material over another to create a finished product. Overmolding can be done with a variety of materials, such as thermoplastic elastomers (TPE), thermoplastic polyurethane (TPU), silicone rubber, polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). In this article, we will discuss these materials in detail and help you understand which one to choose for your next project.

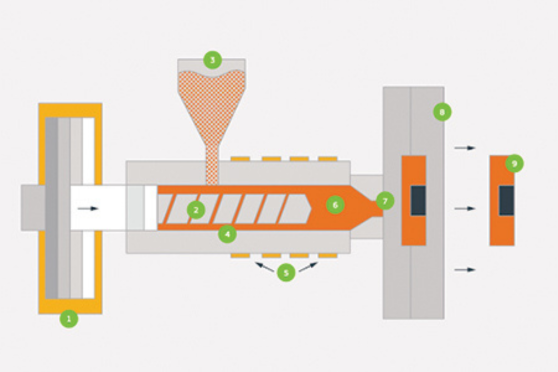

2. What is overmolding?

Overmolding is a manufacturing process in which two or more materials are molded together to create a single finished product. The process involves molding one material over another to create a finished product. The primary advantage of overmolding is that it can improve the aesthetics and functionality of a product. For example, over-molding can be used to create a soft grip for a product, which can improve the user's experience. Overmolding can also be used to create a durable outer layer for a product, which can protect the inner layer from damage.

3. Types of Overmolding Materials

-

Thermoplastic Elastomers (TPE)

Thermoplastic elastomers (TPE) are a popular choice for overmolding. They are a type of thermoplastic polymer that exhibits rubber-like properties. TPE is easy to mold and can be used in a variety of applications. TPE is also available in a variety of durometers, which makes it easy to create products with different levels of hardness.

-

Thermoplastic Polyurethane (TPU)

Thermoplastic polyurethane (TPU) is another popular choice for overmolding. TPU is a type of thermoplastic elastomer that exhibits excellent durability and abrasion resistance. TPU is also resistant to oil, grease, and chemicals, which makes it an ideal choice for products that will be exposed to harsh environments.

-

Silicone Rubber

Silicone rubber is a popular choice for overmolding due to its excellent flexibility and durability. Silicone rubber is also resistant to extreme temperatures, which makes it an ideal choice for products that will be exposed to high or low temperatures. Silicone rubber is also biocompatible.

-

Polypropylene (PP)

Polypropylene (PP) is a popular choice for overmolding due to its excellent chemical resistance and low cost. PP is a thermoplastic polymer that can be easily molded and is available in a variety of colors. PP is also lightweight and has a high resistance to fatigue, which makes it an ideal choice for products that will be used frequently.

-

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile butadiene styrene (ABS) is a popular choice for overmolding due to its excellent strength and rigidity. ABS is a thermoplastic polymer that can be easily molded and is available in a variety of colors. ABS is a great option for products that will be exposed to hostile conditions because it is both impact- and chemical resistant.

-

Polycarbonate (PC)

Polycarbonate (PC) is a popular choice for overmolding due to its excellent transparency and impact resistance. PC is a thermoplastic polymer that can be easily molded and is available in a variety of colors. PC is also resistant to high temperatures and has excellent dimensional stability, which makes it an ideal choice for products that require high precision.

4. Applications of Overmolding Materials

Overmolding materials can be used in a variety of applications, including:

- Electrical connectors

- Automotive components

- Medical devices

- Consumer goods

- Aerospace components

- Industrial equipment

5. Advantages of Overmolding

Overmolding provides a number of advantages, including:

- Improved aesthetics

- Enhanced functionality

- Increased durability

- Improved grip

- Protection from environmental factors such as heat, moisture, and chemicals

- Reduced production costs

- Reduced assembly time

6. Choosing the Right Overmolding Material

Choosing the right overmolding material can be challenging, as each material has its own advantages and disadvantages. Some factors to consider when choosing an overmolding material include:

- Environmental elements like humidity, temperature, and chemicals:

- Required level of durability

- Required level of precision

- Required level of flexibility

- Required level of grip

- Required level of transparency

- Production cost

7. Overmolding with Dowell Moulds

Dowell Moulds is a leading manufacturer of high-quality molds for over-molding applications. Dowell Moulds offers a wide range of molds for over-molding applications, including thermoplastic elastomers (TPE), thermoplastic polyurethane (TPU), silicone rubber, polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). Dowell Moulds also offers custom molding services, which can help you create the perfect over-molding solution for your needs.

8. Conclusion

Overmolding is a popular process used in the manufacturing industry to create a single product that is made up of two or more materials. The most commonly used over-molding materials include thermoplastic elastomers (TPE), thermoplastic polyurethane (TPU), silicone rubber, polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). Each material has its own advantages and disadvantages, and choosing the right material depends on a variety of factors. If you are a mould manufacturer in India or work with Dowell Moulds, be sure to consider these factors when choosing an over-molding material for your next project.

9. FAQs

Q1. What is over-molding?

Overmolding is a manufacturing process in which two or more materials are molded together to create a single finished product.

Q2. What are the advantages of over-molding?

The advantages of over-molding include improved aesthetics, enhanced functionality, increased durability, improved grip, protection from environmental factors, reduced production costs, and reduced assembly time.

Q3. What are some common applications of over-molding materials?

Common applications of over-molding materials include electrical connectors, automotive components, medical devices, consumer goods, aerospace components, and industrial equipment.

Q4. How do I choose the right over-molding material for my project?

When choosing an over-molding material, consider factors such as environmental factors (temperature, moisture, and chemicals), the required level of durability, the required level of precision, the required level of flexibility, the required level of grip, the required level of transparency, and production cost.

Q5. What is Dowell Moulds?

Dowell Moulds is a leading manufacturer of high-quality molds for over-molding applications, offering a wide range of molds for over-molding applications, including TPE, TPU, silicone rubber, PP, ABS, and PC. Dowell Moulds also offers custom molding services.