Dowell Moulds is proud to hold the ISO 9001:2015 certification.

Dowell Moulds is proud to hold the ISO 9001:2015 certification.

(600 x 450 px) (3).jpg)

(600 x 450 px) (4).jpg)

(600 x 450 px) (1).jpg)

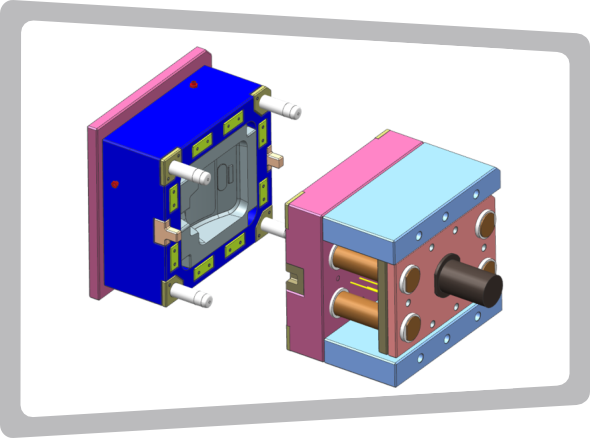

With years of experience, Dowell Moulds specializes in crafting custom Dowell that are precisely tailored to meet each clients unique design vision and production needs. Utilizing the latest technological advancements, we ensure optimal efficiency and durability in every mold we create.

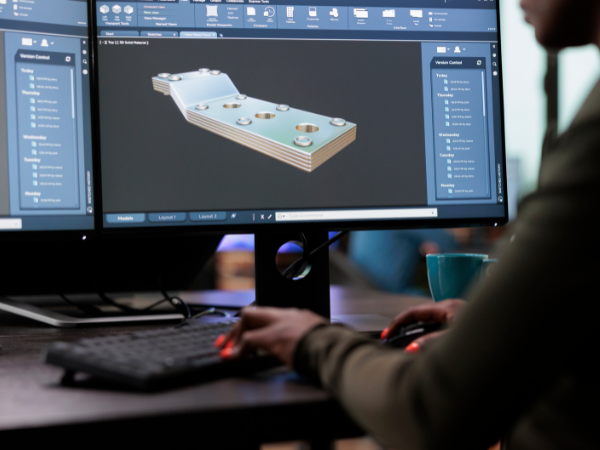

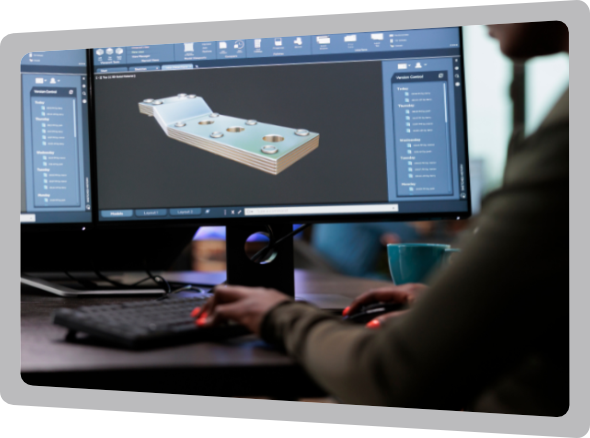

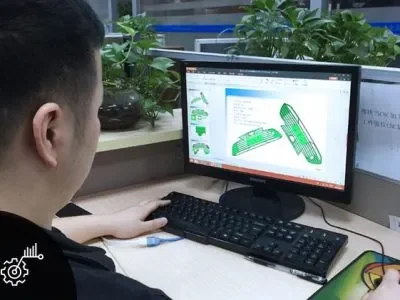

Product Design at Dowell Moulds focuses on precision-engineered moulds using advanced CAD/CAM technology, ensuring high-quality, efficient, and cost-effective manufacturing solutions.

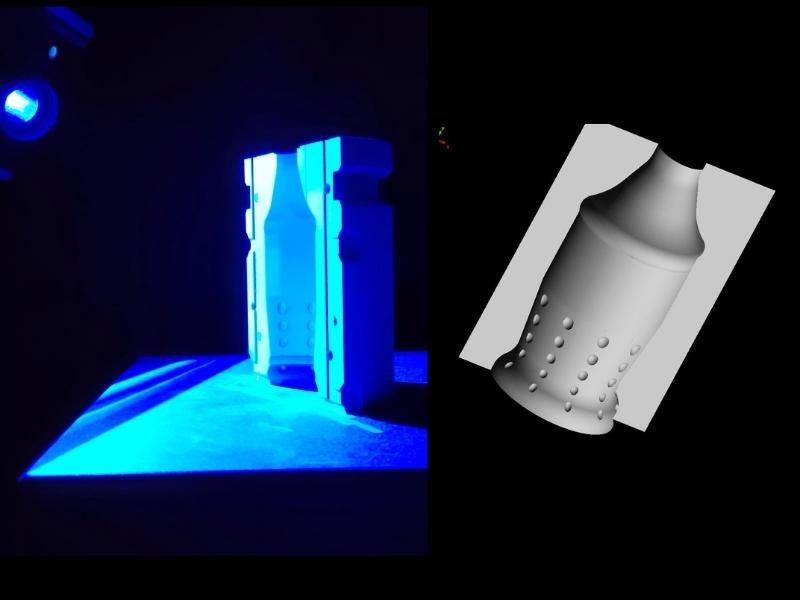

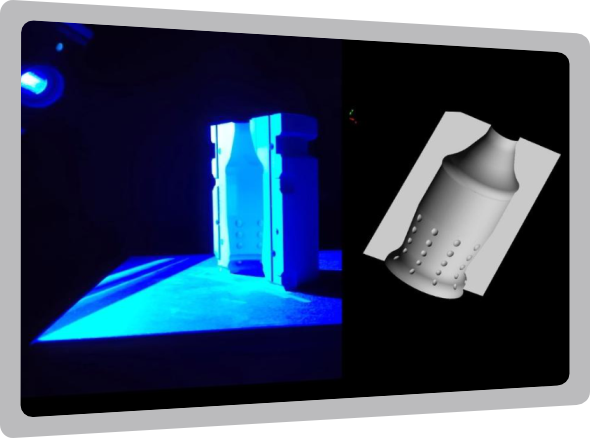

Reverse Engineering at Dowell Moulds involves analyzing and reconstructing existing moulds using advanced 3D scanning and CAD technology to enhance performance, optimize design, and improve manufacturing efficiency.

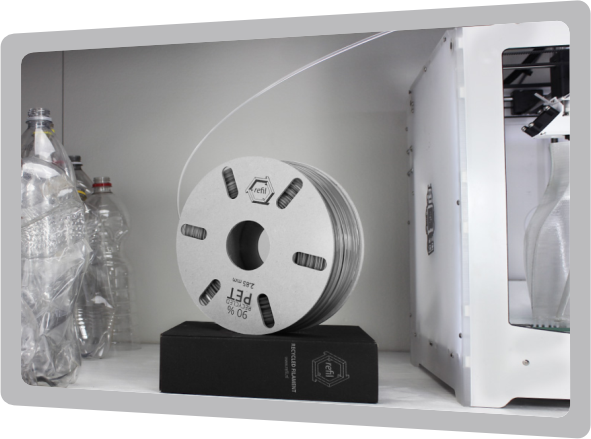

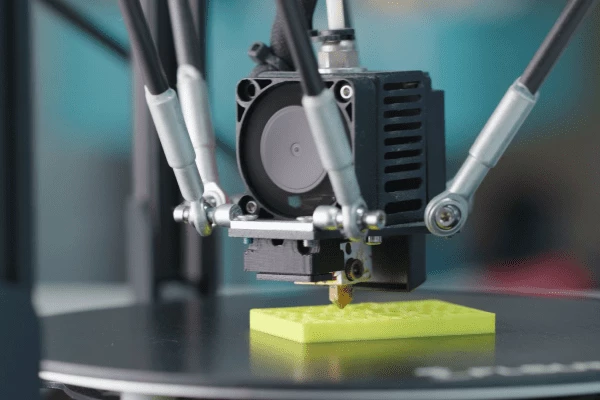

Prototyping at Dowell Moulds focuses on creating precise, functional prototypes using advanced manufacturing techniques, including 3D printing, ensuring design validation, efficiency, and high-quality mould production.

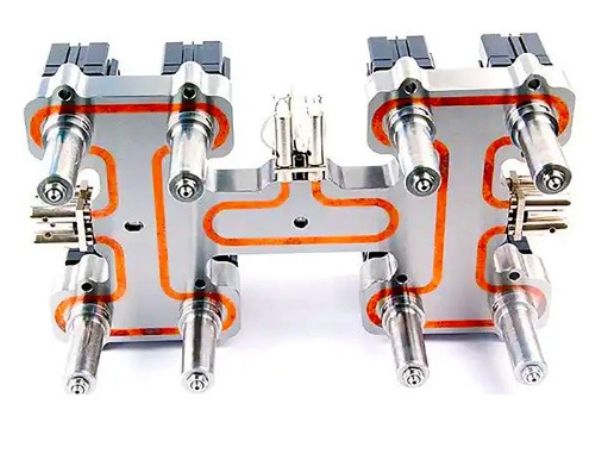

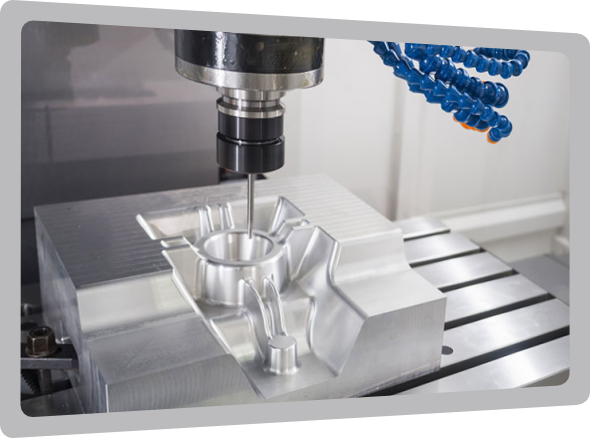

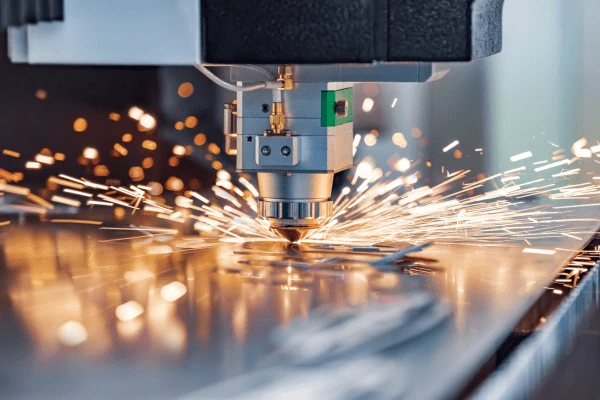

Dowell Moulds specializes in precision CNC machining for high-quality mould manufacturing. We deliver accurate, durable, and efficient mould solutions tailored to your needs.

Dowell Moulds offers advanced EDM (Electrical Discharge Machining) for precise and intricate mould manufacturing, ensuring high-quality and efficient production.

86046_edm.png)

Dowell Moulds offers precision wire cutting for intricate and high-accuracy mould manufacturing, ensuring superior quality and efficiency.

Dowell Moulds provides precision grinding services for high-quality mould manufacturing, ensuring smooth finishes and superior accuracy.

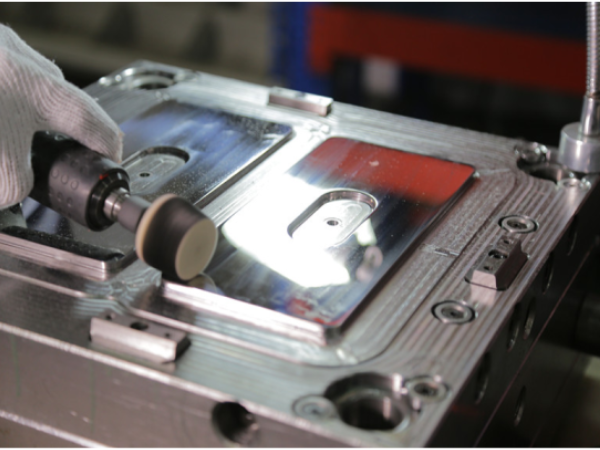

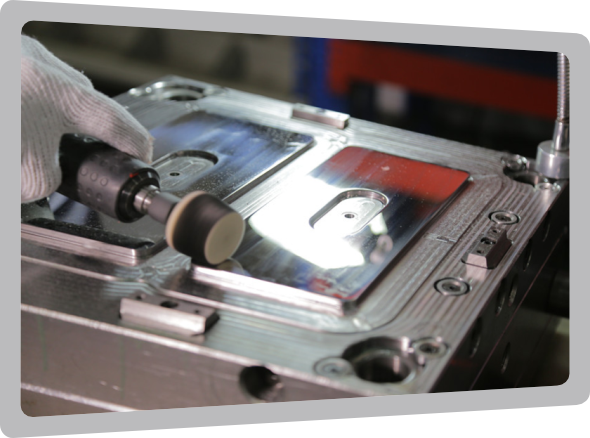

Dowell Moulds offers expert polishing services for mould manufacturing, ensuring smooth, high-quality finishes with precision and durability.

Dowell Moulds specializes in Multi-Axis CNC and VMC machining, delivering high-precision mould manufacturing with superior accuracy and efficiency.

Dowell Moulds offers comprehensive Quality & Testing services, including CMM inspection, ensuring the highest standards of precision, accuracy, and performance for all our mould manufacturing processes.

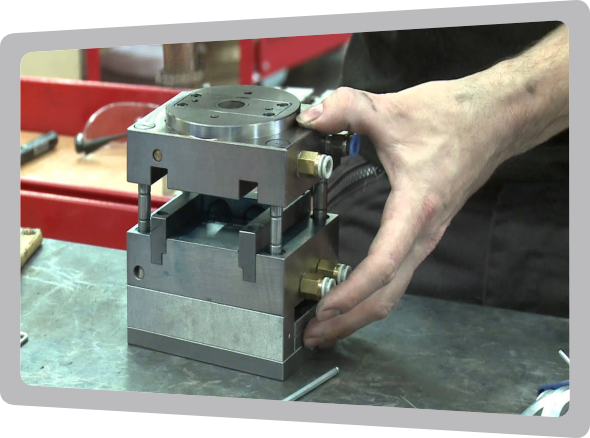

At Dowell Moulds, our Mould Trial & Testing Facility ensures every mould meets the highest standards of performance, durability, and precision. Using Aoki, HUSKY, and Ferromatik Milacron machines, we conduct rigorous testing to guarantee flawless functionality and optimal efficiency before final delivery.

Dowell Moulds is backed by expert metallurgists and material science professionals, ensuring the selection of the right materials and optimal processing techniques for superior mould quality, performance, and longevity.

Dowell Moulds' experienced product design team works closely with clients to refine and optimize design specifications, ensuring a perfect balance of technical, economic, and aesthetic factors to meet end-user requirements.

With years of expertise, Dowell Moulds specializes in creating custom molds that align seamlessly with clients' design goals and manufacturing requirements. Utilizing the latest technology, we ensure maximum efficiency and durability.

Dowell Moulds Plastic Mould enhances quality and productivity in custom mold and product manufacturing through rigorous engineering, addressing molding issues and optimizing design and tool production efficiency.

Dowell Moulds offers cost-effective, high-volume plastic injection molding, creating high-quality parts for diverse industries, with specialized services like ISO8 cleanroom production for the medical sector.

In CNC Machining, Dowell Moulds employs advanced machinery to fabricate precise components directly from CAD files, offering high precision, repeatability, and compatibility with a variety of materials.

Dowell Moulds rapid prototyping techniques, including CNC Machining, 3D Printing, Vacuum Casting, and Silicone Overmolding, swiftly and accurately materialize innovative designs.

Dowell Moulds leverages 3D printing technology to create intricate parts directly from digital models, providing quick turnarounds, design flexibility, and cost-effective low-volume production.

Dowell Moulds offers diverse surface finishing techniques for functional or aesthetic purposes on CNC machined metals, injection-molded plastics, and fabricated sheet metal, considering factors like material, color, texture, and cost.

We can provide one-stop service

Our comprehensive product design services ensure that we work with our clients from the beginning stages to make improvements on all technical drawings, including 2D and 3D files, to ensure the best possible outcome for each project.

Our expert team utilizes state-of-the-art technology and innovative strategies to deliver top-quality mould designs that are optimized for efficient and effective production.

Dowell Moulds precision mold manufacturing process combines advanced technology with expert craftsmanship to deliver high-quality, durable moulds for our clients.

Dowell Moulds injection moulding process leverages cutting-edge equipment and techniques to produce top-quality plastic components for a wide range of industries

Dowell Moulds injection moulding process leverages cutting-edge equipment and techniques to produce top-quality plastic components for a wide range of industries

All raw materials are verified for conformity upon receipt. Our Quality Control team inspects dimensions, hardness, and more to ensure molds’ long service life.

Continuous inspections during manufacturing ensure all processes meet quality standards. This includes precision checks and defect detection.

Every final product undergoes thorough inspection to confirm it meets customer requirements and industry standards before delivery.