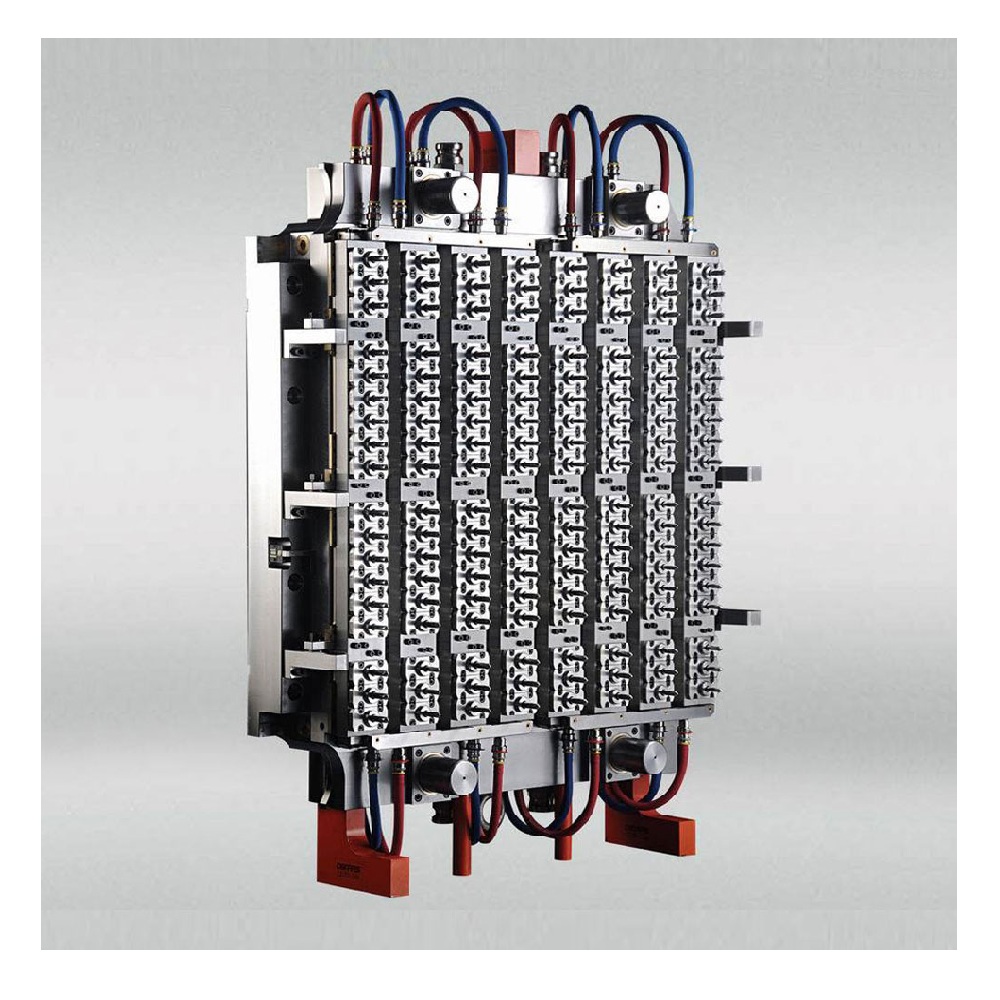

HOT RUNNER PET PREFORM MOULD

Features:

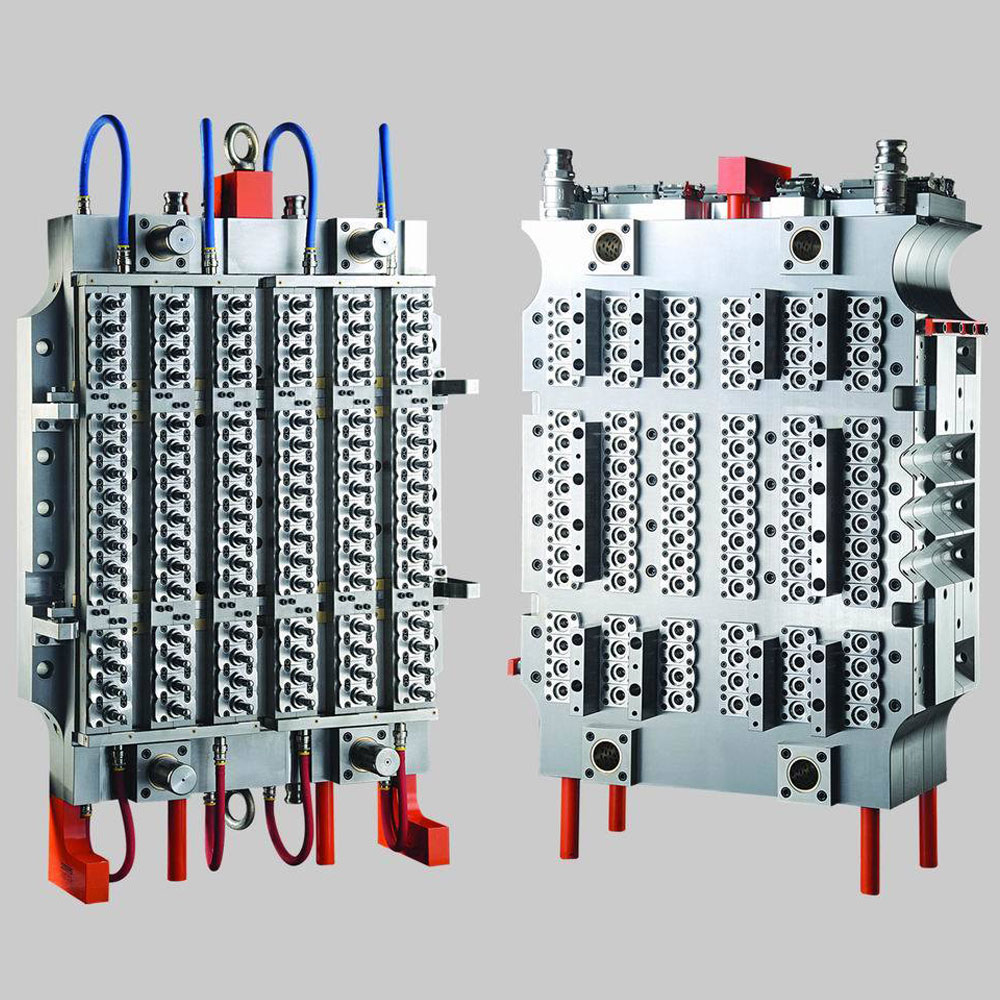

- Moulds up to 144 cavitation

- Neck Sizes from 12 mm to 140 mm

- Wall thickness as low as 1.6 mm

- Micro pitching for smaller neck sizes

- PMC Plates with take-out arms

- Fast Cycle Time among all contemporary supplies

- Specialized tools steel for mould Base and moulding stacks

- Good surface finish of products

- Longer Operating life for mould

Specifications:

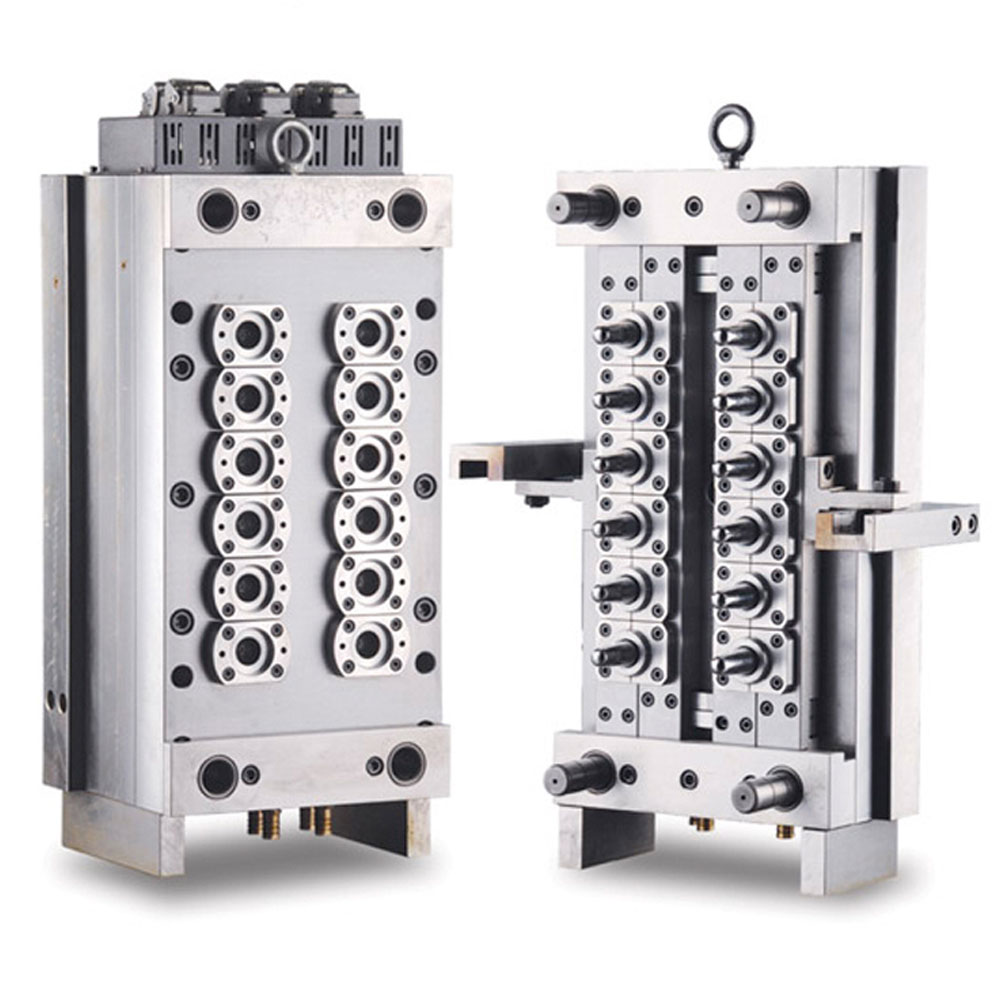

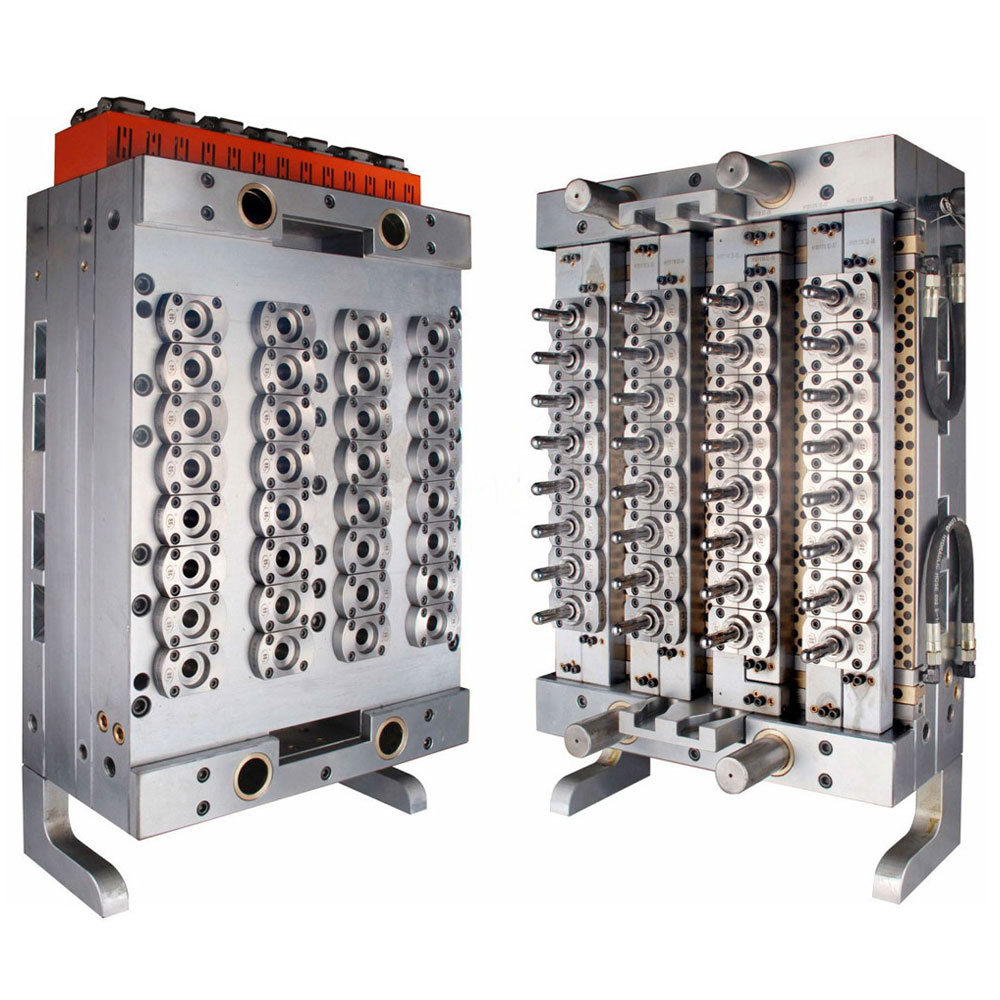

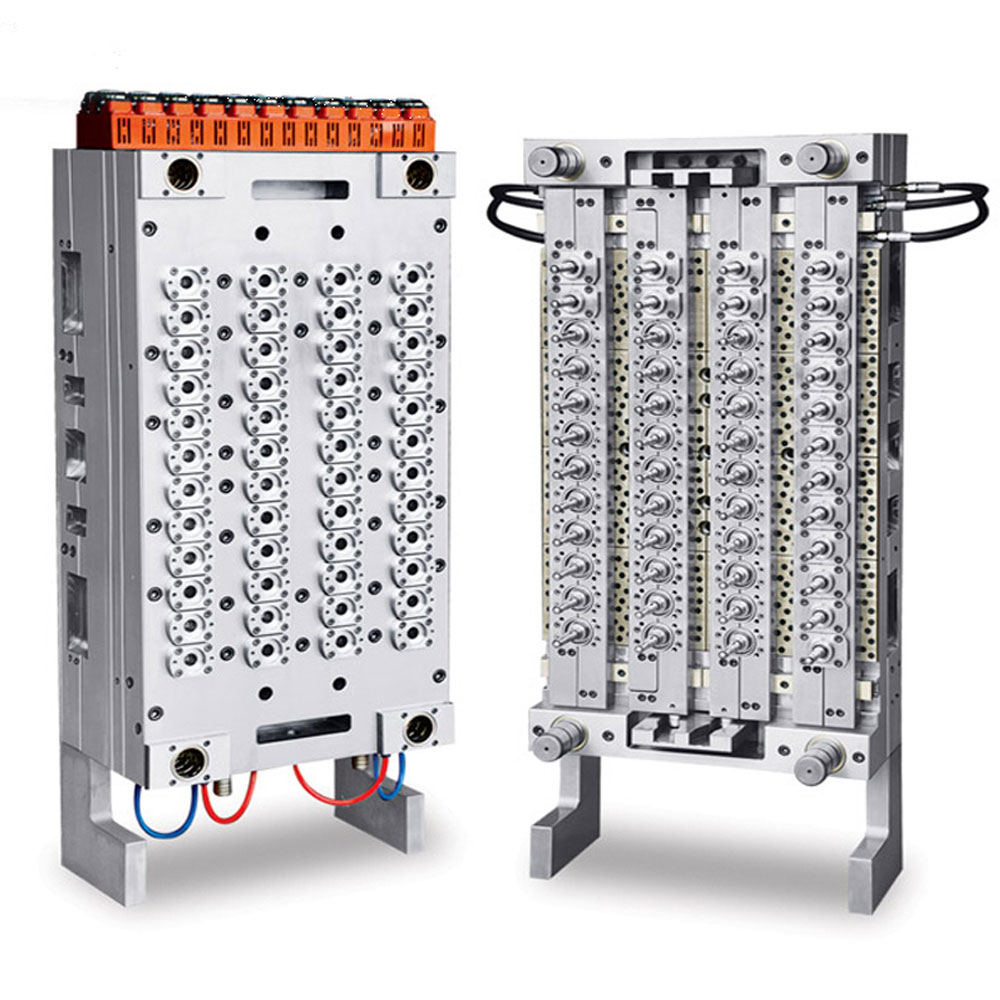

- 96 Cavity Valve Gate Hot Runner PET Preform Mould.

- 72 Cavity Valve Gate Hot Runner PET Preform Mould.

- 48 Cavity Valve Gate Hot Runner PET Preform Mould.

- 32 Cavity Valve Gate Hot Runner PET Preform Mould.

- 24 Cavity Valve Gate Hot Runner PET Preform Mould.

- 12 Cavity Valve Gate Hot Runner PET Preform Mould.

- 08 Cavity Valve Gate Hot Runner PET Preform Mould.