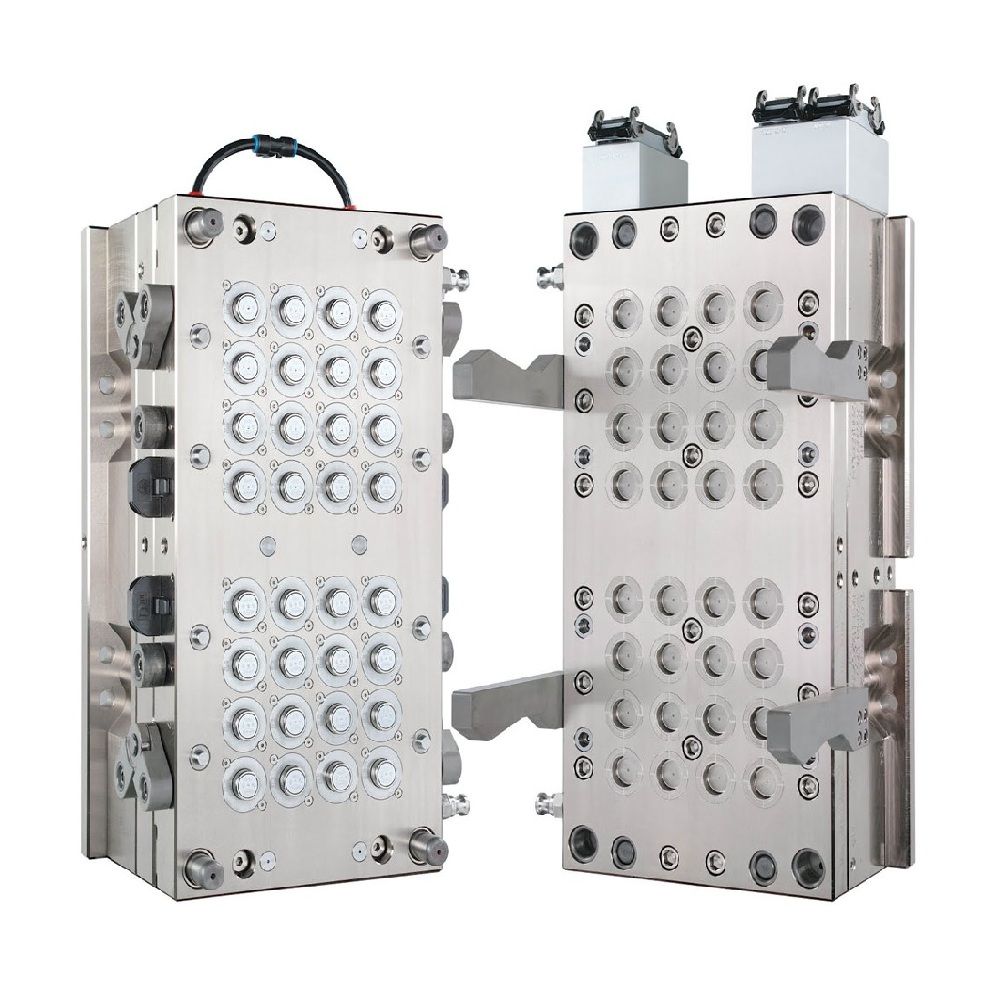

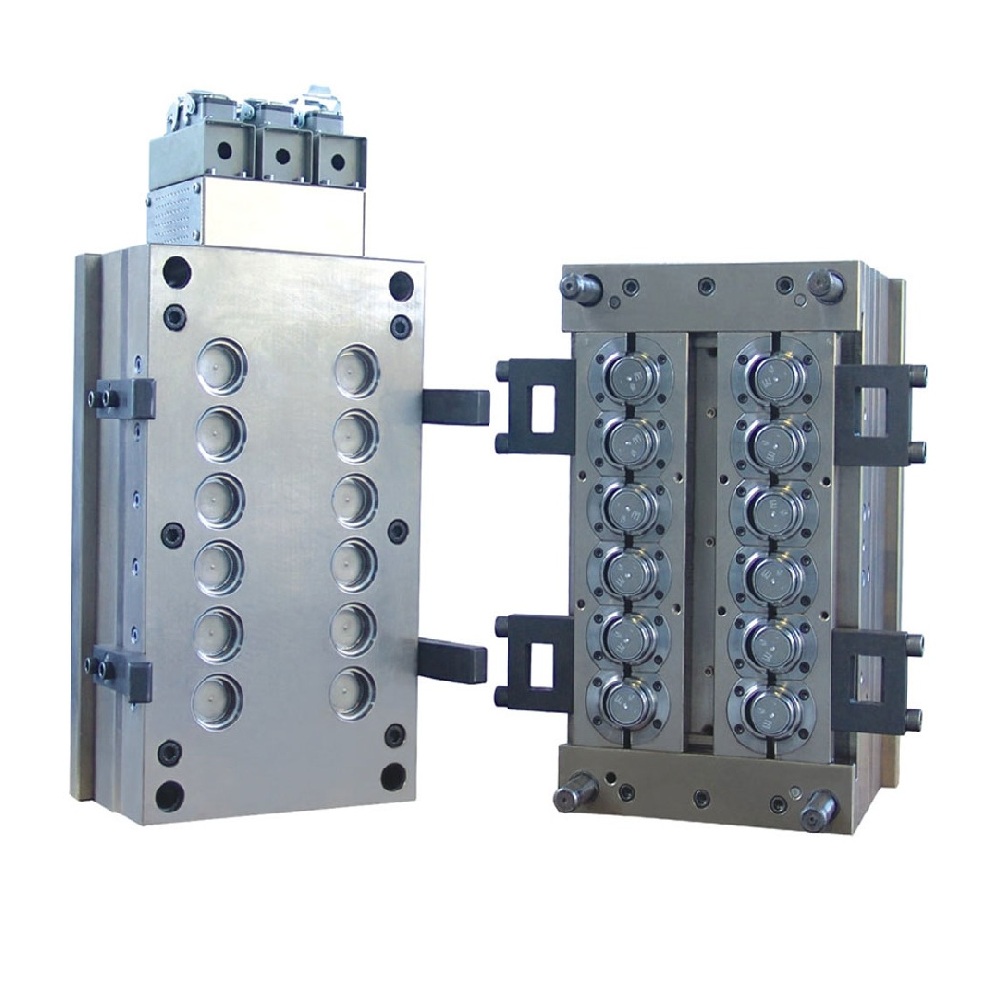

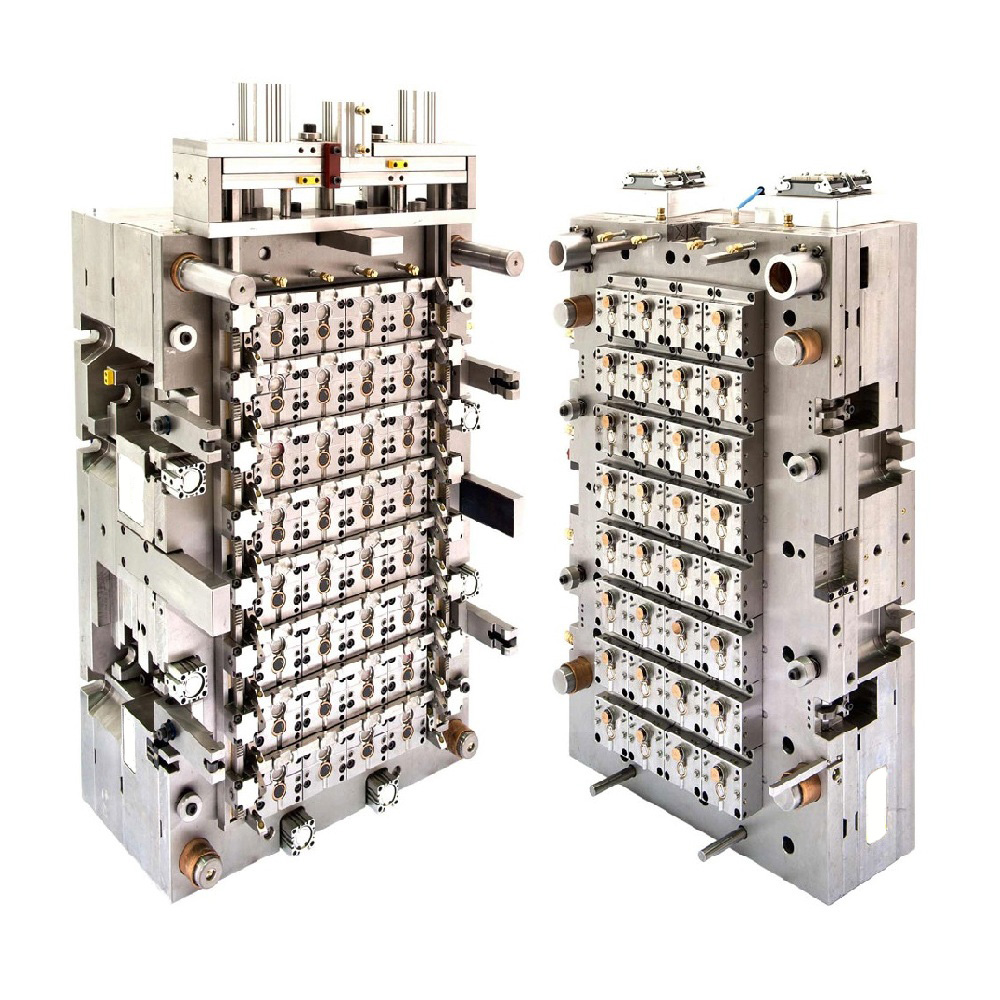

HOT RUNNER CAP MOULD

Features:

- Moulds up to 72 cavities for high-capacity production

- Precise temperature control for uniform cap moulding

- Fast cycle times, increasing overall production efficiency

- No runner waste, max material usage and reducing costs

- Flexible gate positioning for superior cap aesthetics

- Wear-resistant steel for mould base and components

- Consistent dimensional accuracy and surface finish

- Ideal for complex cap designs and lightweight applications

- Low maintenance with long operational life

Specifications:

- Mould Material: High Grade Steel

- Mould Cavity: Upto 128 Cavity.

- Mould Life: Greater than 1,000,000 shots.

.png)