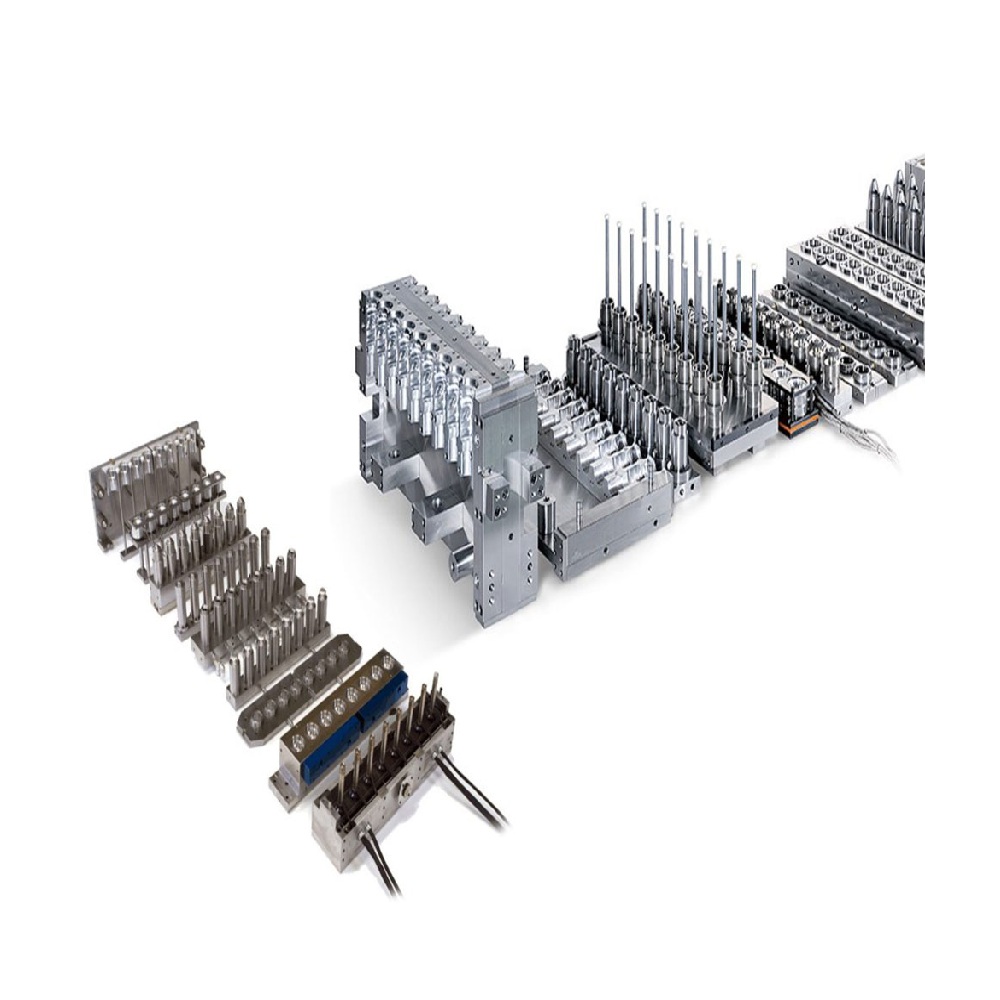

SPARE PARTS

We believe that excellent quality, satisfactory customer service and continuous innovation will propel us to set the benchmark for this industry and add everlasting satisfaction to our customers. We provide all types of spare parts of hot runner and cold runner mould. we offer standard parts and customized mould parts.

Specifications:

- Optimum stack design enables lesser cycle time.

- Longer flash free performance.

- Long service life.

- Robustness.

- Sturdiness.

.png)