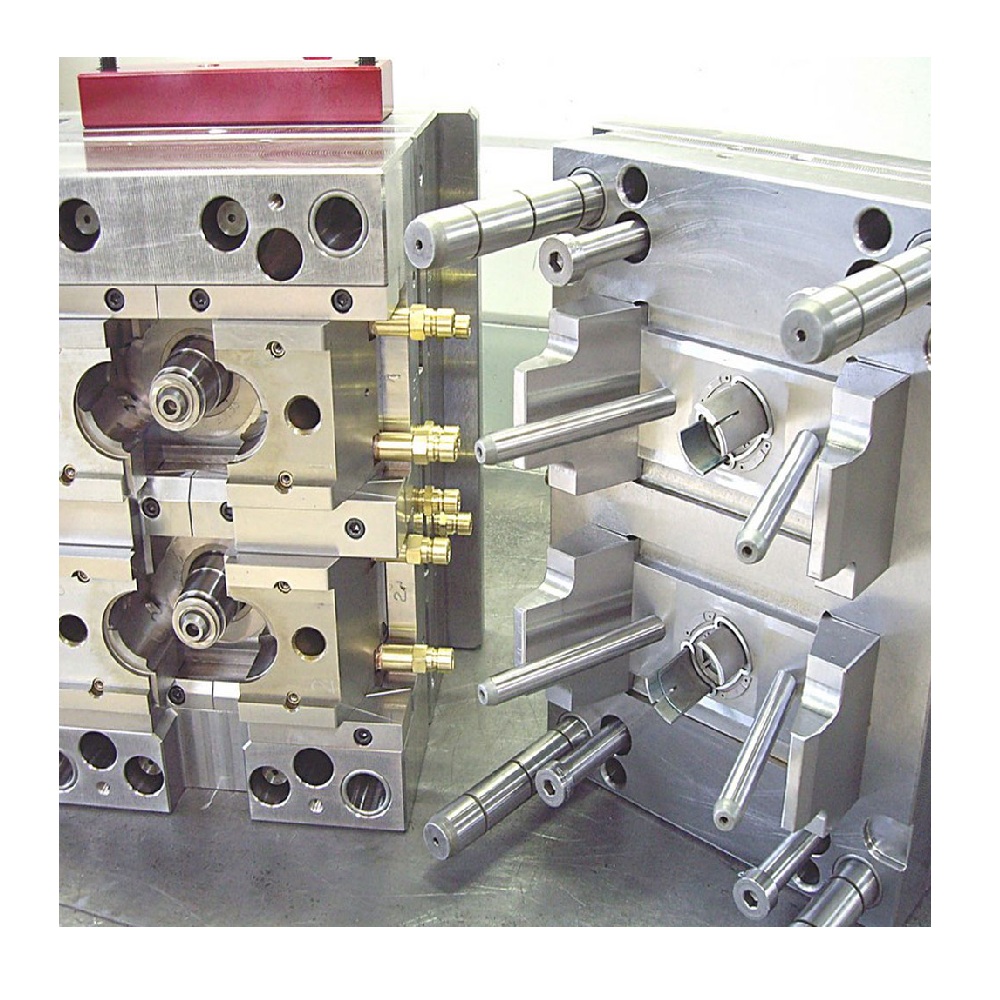

IBM mould manufacturer in India

In IBM mould manufacturing Companies the Injection Blow Mould (IBM) is a derivative by the plastic manufacturing industries to produce hollow plastic items like bottles, jars and containers. IBM mould makers optimize the Injection Blow Moulding work by combining two techniques of injection moulding and blow moulding to give high value products that are précised and in equal thickness.

The IBM Process:

These are the key processes every IBM mould manufacturer and IBM mould exporters must thoroughly follow with respect to quality assurance and maintaining the efficiency of manufactured products in the supply chain market.

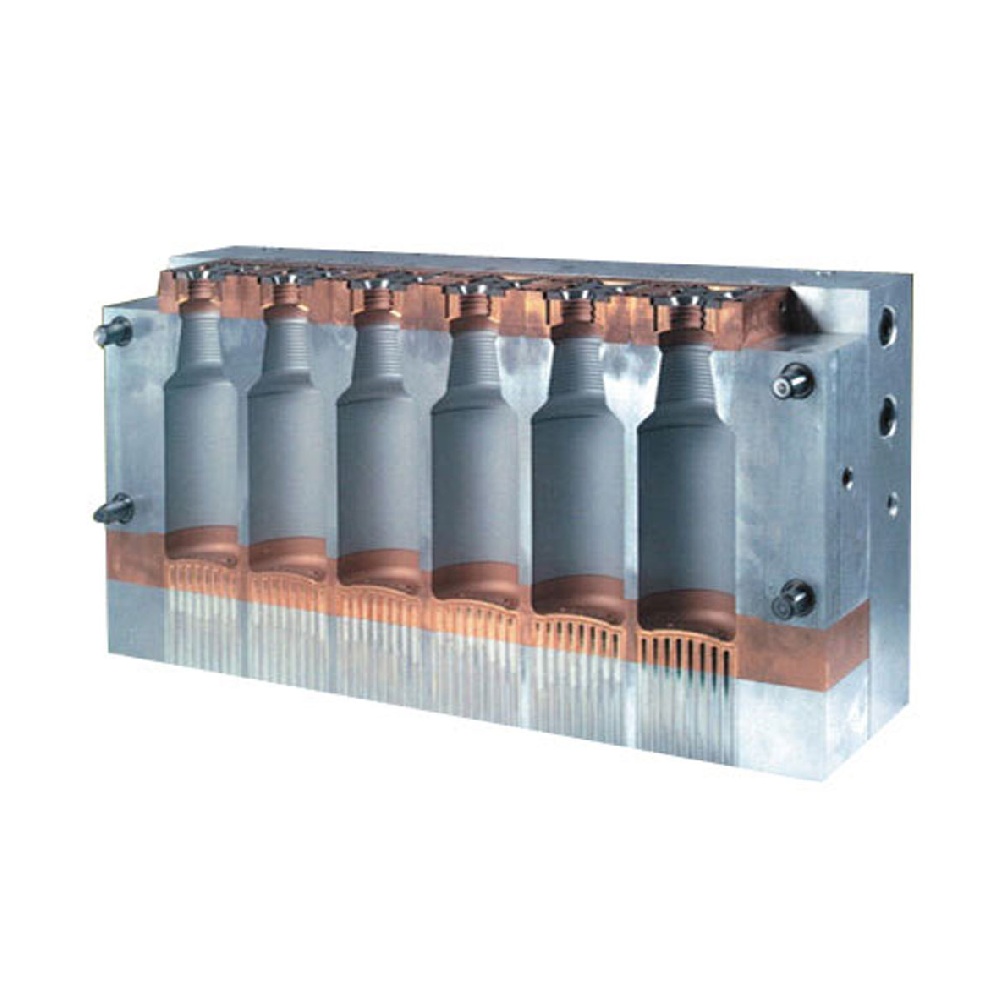

- Injection: The first step involves the use of the preform mold in which molten plastic is injected to create tube-like piece with closed end referred to as preform.

- Blowing: The preform is then taken to the blow moulding section whereby the preform is first placed inside a cavity and then inflated to create the shape of the final product.

- Moulding: At last, the shaped product is cooled and then removed from the mould. Formed product; in the last process, the final shaped product is cooled and expelled from the mould.

Advantages:

- Precision and Consistency: This makes IBM to have thin and constant thickness in the walls making it appropriate for manufacturing small items that require high tolerance.

- Efficient Production: It is highly effective since the two operations are done in one go, cycle time is cut and thus the mass production of the hollow plastic products noted above.

- Material Savings: IBM uses performance that is in the close shape of the final product, this helps in minimization of material usage particularly plastic.

Applications

- Packaging: Frequently applied in manufacturing of the bottles for soft and alcoholic beverages, cosmetics, medicines, and many other products.

- Consumer Goods: Applied to such productions as jars, containers and other items that are made up of thin-walled hollow plastic.

- Medical Industry: Based on this case, it is clear that IBM is utilized to produce containers and bottles for medical selling and pharmaceutical use.

With the increasing demand for efficient and versatile moulds, you may find it beneficial to explore a wider range of options. Our Blow Moulds offers various solutions, including both EBM and IBM moulds, tailored to diverse industrial needs.

Indications of precise injection blow moulds in India

India has also seen more and more tendency of Clients requesting Injection Blow Mould. The injection blow mould design service provider can design the mould for specific products and their specifications of geometry and size along with materials to be used. Custom injection blow moulds as presented above are crucial to anybody who is in business and would wish to create product variances.

Why Work with an IBM Mould Manufacturer in India?

- Expertise: Today Indian manufacturers of plastic injection blow moulds boast of having gained adequate experience in designing as well as manufacturing excellent quality consistent moulds. Thanks to their experience, the moulds are produced according to the industry norms and the clients’ requirements.

- Customization: Most mould manufacturers in India who deal in mould manufacturing for IBM are flexible and can adjust their moulds according to the specifications of a business’s products.

- Cost-Effective Solutions: India is reckoned for its competitive price structure without making compromise in quality, thus making India a preferred IBM mould sourcing destination.

- Reliable Supply: Indian mould suppliers of IBM are trusted for their punctuality in delivery of the produced moulds, and the production lines do not get affected due to constraints in time.

Injection Blow Moulds (IBM) is specifically a very vital tool used in creating hollow plastic products. To meet high quality, efficiency and accuracy, business organizations in search of Injection Blow Mould Manufacturing services in India need to engage the help of a competent Injection Blow Mould Manufacturer. Competent Indian manufacturers specialize in the design of IBM, customized specifications, and secure sourcing, making it possible for you to get optimum products at reasonable prices!

Explore Injection Stretch Blow Mould (ISBM) for advanced single-stage moulding alongside IBM!