Dowell Moulds' experienced product design team works closely with clients to refine and optimize design specifications, ensuring a perfect balance of technical, economic, and aesthetic factors to meet end-user requirements.

Core Values

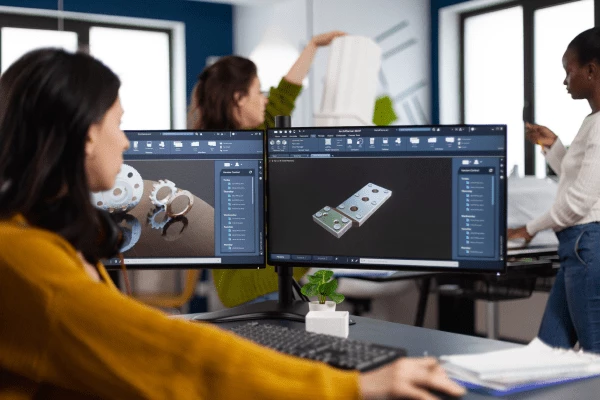

Product Design

Dowell Moulds' experienced product design team works closely with clients to refine and optimize design specifications, ensuring a perfect balance of technical, economic, and aesthetic factors to meet end-user requirements.

Mould Design

With years of expertise, Dowell Moulds specializes in creating custom molds that align seamlessly with clients' design goals and manufacturing requirements. Utilizing the latest technology, we ensure maximum efficiency and durability.

Mould Manufacturing

Dowell Moulds Plastic Mould enhances quality and productivity in custom mold and product manufacturing through rigorous engineering, addressing molding issues and optimizing design and tool production efficiency.

Plastic Injection

Dowell Moulds offers cost-effective, high-volume plastic injection molding, creating high-quality parts for diverse industries, with specialized services like ISO8 cleanroom production for the medical sector.

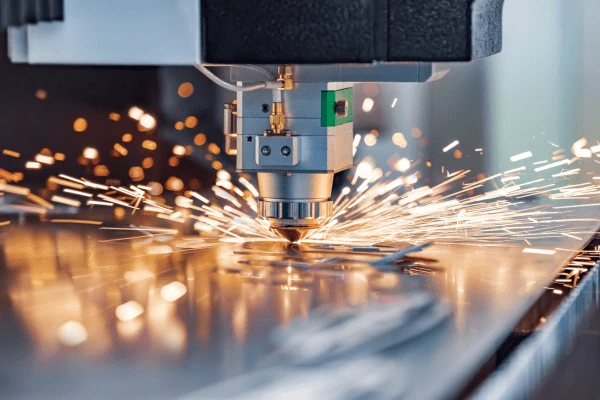

CNC Machining

In CNC Machining, Dowell Moulds employs advanced machinery to fabricate precise components directly from CAD files, offering high precision, repeatability, and compatibility with a variety of materials.

Rapid prototyping

Dowell Moulds rapid prototyping techniques, including CNC Machining, 3D Printing, Vacuum Casting, and Silicone Overmolding, swiftly and accurately materialize innovative designs.

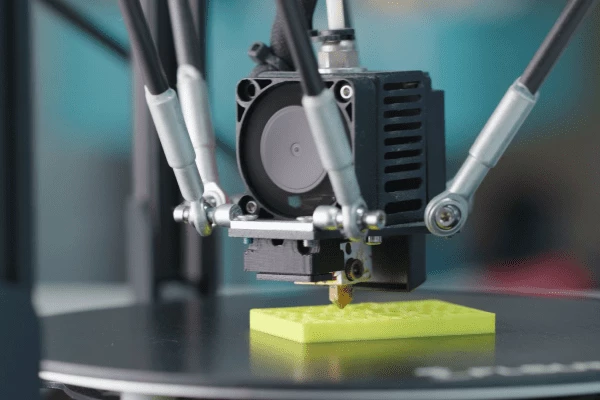

3D Printing

Dowell Moulds leverages 3D printing technology to create intricate parts directly from digital models, providing quick turnarounds, design flexibility, and cost-effective low-volume production.

Surface Finishing

Dowell Moulds offers diverse surface finishing techniques for functional or aesthetic purposes on CNC machined metals, injection-molded plastics, and fabricated sheet metal, considering factors like material, color, texture, and cost.