Plastic injection moulding is a popular manufacturing process that involves melting plastic pellets and injecting them into a mould to create a specific shape or design. However, the process is not as straightforward as it appears. To achieve high-quality plastic parts, manufacturers need to consider various factors, including the type of mould used in the process. In this article, we will discuss the different types of mould in plastic injection moulding that plastic mould manufacturers in India, like Dowell Moulds, should be aware of.

Table of Contents

1. Introduction

2. What is Plastic Injection Moulding?

3. The Importance of Choosing the Right Mould

4. Types of Mould in Plastic Injection Moulding

- Two-Plate Mould

- Three-Plate Mould

- Hot Runner Mould

- Cold Runner Mould

- Family Mould

- Insert Moulding

- Stack Moulding

- Unscrewing Moulding

- Gas-Assisted Moulding

- Thin Wall Moulding

5. Factors to Take into Account While Selecting a Mould

6. Conclusion

7. FAQs

1. Introduction

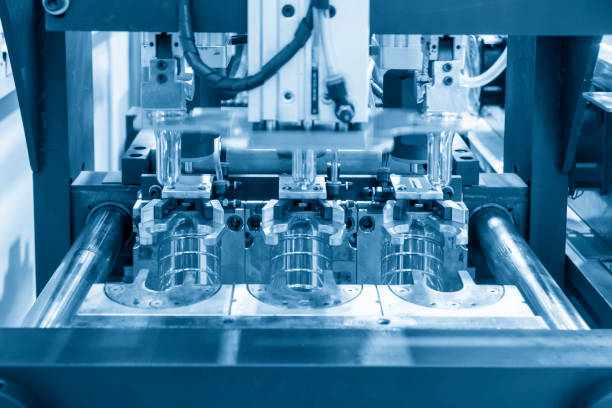

Plastic injection moulding is a widely used manufacturing process that involves the production of plastic parts by injecting molten plastic material into a mould. The process is extremely adaptable, and it may be used to create a wide range of goods, from small, precise components to huge, complicated elements.

The use of plastic injection moulding has revolutionized the manufacturing industry by providing a fast, efficient, and cost-effective method of production. It has replaced traditional manufacturing methods such as machining, forging, and casting, which are slower and more expensive.

2. What is Plastic Injection Moulding?

Plastic injection moulding is a manufacturing process that involves injecting molten plastic material into a mould. The process starts by melting plastic pellets or granules, which are then injected into a mould cavity. The plastic is then allowed to cool and solidify, after which the mould is opened, and the part is ejected.

3. The Importance of Choosing the Right Mould

Choosing the right mould is critical to the success of plastic injection moulding. The type of mould used in the process can affect the quality of the final product, as well as the production time and cost. Therefore, it is important for plastic mould manufacturers in India, like Dowell Moulds, to choose the right mould for their production needs.

4. Types of Mould in Plastic Injection Moulding

There are several types of mould used in plastic injection moulding. Here are a few of the most common:

1. Two-Plate Mould

The two-plate mould is the simplest and most commonly used mould in plastic injection moulding. It consists of two plates that are held together by the mould base. The plastic material is injected into a cavity between the two plates, and the part is ejected when the mould is opened.

2. Three-Plate Mould

The three-plate mould is similar to the two-plate mould, but it has an additional plate that separates the runner and gate from the part. This type of mould is commonly used for parts that require side gating or when the runner and gate need to be removed from the part.

3. Hot Runner Mould

The hot runner mould is a type of mould that uses a heated manifold to inject plastic material into the mould cavity. The plastic material is kept molten in the runner system, which eliminates the need for a cold runner. This results in less material waste and faster cycle times.

4. Cold Runner Mould

The cold runner mould is a traditional mould that uses a separate runner system to deliver the plastic material to the mould cavity. The runner system is usually ejected with the part, which results in more material waste and longer cycle times.

5. Family Mould

The family mould is a type of mould that allows for the production of multiple parts in one mould. It consists of multiple cavities that are designed to produce different parts simultaneously. This leads to shorter production times and lower costs.

6. Insert Moulding

Insert moulding is a type of moulding that involves inserting a metal or plastic component into the mould before injecting the plastic material. This process is commonly used for parts that require specific components, such as electrical connectors or threaded inserts.

7. Stack Moulding

Stack moulding is a type of moulding that involves stacking multiple moulds on top of each other to produce multiple parts simultaneously. This process is commonly used for high-volume production and can result in significant cost savings.

8. Unscrewing Moulding

Unscrewing moulding is a type of moulding that involves unscrewing the mould to release the part. This process is commonly used for parts that have internal threads or other complex features that require a threaded mould.

9. Gas-Assisted Moulding

Gas-assisted moulding is a type of moulding that involves injecting gas into the mould cavity to push the plastic material into the corners of the cavity. This process is commonly used for parts that have thick walls or complex geometries.

10. Thin Wall Moulding

Thin wall moulding is a type of moulding that involves producing plastic parts with very thin walls. This process requires special moulds that can withstand the high pressures needed to inject the plastic material into the mould cavity.

5. Factors to Take into Account While Selecting a Mould

When choosing a mould for plastic injection moulding, there are several factors to consider. These include the part design, material, production volume, and budget. It is important to choose a mould that is designed to produce high-quality parts efficiently and cost-effectively.

6. Conclusion

Choosing the right mould is critical to the success of plastic injection moulding. By understanding the different types of mould available, plastic mould manufacturers in India, like Dowell Moulds, can choose the right mould for their production needs. Whether it's a simple two-plate mould or a more complex gas-assisted mould, each type has its own advantages and disadvantages. It is important to consider all factors when choosing a mould to ensure the best possible results.

7. FAQs

1. What is plastic injection moulding?

Ans. Plastic injection moulding is a manufacturing process that involves injecting molten plastic material into a mould.

2. What factors should I consider when choosing a mould?

Ans. When choosing a mould, it is important to consider the part design, material, production volume, and budget.

3. What is the most commonly used mould in plastic injection moulding?

Ans. The most commonly used mould in plastic injection moulding is the two-plate mould.

4. What is insert moulding?

Ans. Insert moulding is a type of moulding that involves inserting a metal or plastic component into the mould before injecting the plastic material.

5. What is stack moulding?

Ans. Stack moulding is a type of moulding that involves stacking multiple moulds on top of each other to produce multiple parts simultaneously.