Table of Contents:

-

Introduction

-

Understanding Thermoplastic Elastomers (TPE)

-

TPE Overmolding Process

-

Benefits of Thermoplastic Elastomer Overmolding

-

Overmolding TPE vs. Silicone

-

TPE Overmolding Advantages

-

Overmolding Design Considerations

-

Mould Manufacturers in India for TPE Overmolding

-

Conclusion

1. Introduction

Overmolding, a technique gaining prominence in modern manufacturing, involves molding a thermoplastic material over another to create a single component with enhanced features and functionalities. This process has revolutionized the production of various consumer goods, medical devices, automotive components, and more. One of the materials that has seen a surge in usage for overmolding is thermoplastic elastomers (TPE). In this article, we delve into the intricacies of overmolding with TPE, highlighting its advantages, process, and comparison with other materials like silicone.

Brief Explanation of Overmolding and Its Importance in Manufacturing

Overmolding is a manufacturing process wherein a substrate or base component is encapsulated with another material, typically a thermoplastic, to enhance its properties and aesthetics. This technique not only enhances durability but also allows for intricate designs and customized textures, catering to evolving consumer demands. The encapsulation also ensures a secure bond between the base component and the overmolded material, contributing to the longevity and reliability of the final product.

Mention the Rising Trend of Overmolding with Thermoplastic Elastomers (TPE)

In recent years, there has been a noticeable shift towards using thermoplastic elastomers (TPE) in overmolding processes. TPE, a versatile class of polymers with both thermoplastic and elastomeric properties, is gaining traction due to its exceptional characteristics, making it an ideal choice for overmolding applications. Let's explore the world of TPE and understand why it's becoming a go-to material for overmolding.

2. Guide to Overmolding with TPE

Definition and Composition of TPE

TPE, a unique class of polymers, exhibits characteristics of both thermoplastics and elastomers. It consists of a polymer matrix, often based on polypropylene (PP), polyethylene (PE), or a blend of these, combined with elastomeric phases like rubber. This composition imparts TPE with the ability to be repeatedly heated and molded, akin to thermoplastics, while retaining elasticity and flexibility like traditional elastomers.

Properties and Characteristics of TPE That Make It Suitable for Overmolding

TPE's versatility stems from its exceptional properties, including excellent resilience, high flexibility, good chemical resistance, and remarkable weatherability. Its ability to conform to complex geometries during overmolding while maintaining structural integrity makes it highly desirable for creating intricate and functional product designs.

Types of TPE Commonly Used in Overmolding

Various types of TPEs are available for overmolding, each with distinct properties catering to specific application requirements. Commonly used TPEs include Styrenic Block Copolymers (SBC), Thermoplastic Polyurethanes (TPU), and Thermoplastic Olefins (TPO). SBC provides excellent flow properties and elasticity; TPU offers high abrasion resistance; and TPO combines flexibility with impact strength.

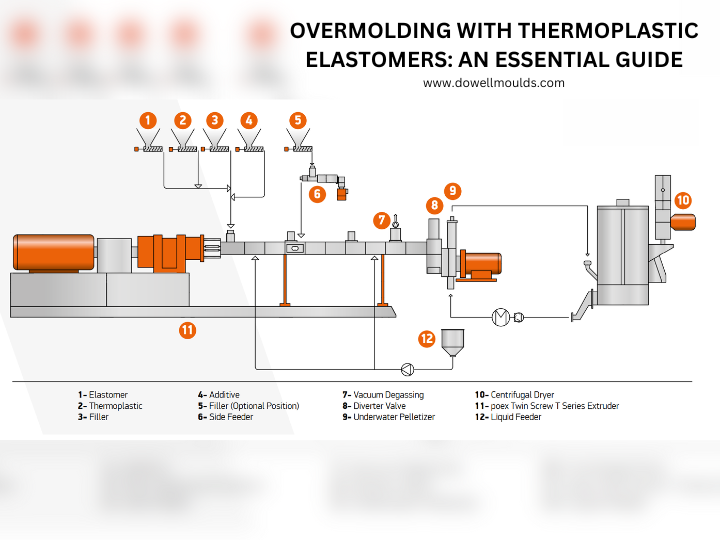

3. TPE Overmolding Process

Step-by-step Guide to the Overmolding Process with TPE

The TPE overmolding process involves several stages, including substrate preparation, material selection, mold design, and injection molding. First, the base component, or substrate, is prepared and inserted into the mold. The TPE pellets are then melted and injected into the mold, overmolding the substrate. After cooling and solidification, the final overmolded product is ejected from the mold.

Explanation of the Injection Molding Technique in Overmolding

Injection molding, a key aspect of TPE overmolding, involves injecting molten TPE into a mold cavity at high pressure. The mold contains the desired shape of the final part. As the TPE cools and solidifies within the mold, it encapsulates the substrate and adopts the mold's contours, resulting in a cohesive, overmolded structure.

Factors Affecting the Success of the TPE Overmolding Process

Achieving a successful TPE overmolding process requires careful consideration of factors such as material selection, mold design, temperature control, injection pressure, and cooling rates. Precision in each of these aspects ensures an overmolded product that meets quality standards and adheres to design specifications.

4. Benefits of Thermoplastic Elastomer Overmolding

Enhanced Product Durability and Longevity

TPE overmolding significantly enhances product durability by providing a protective layer over the substrate, effectively shielding it from wear, tear, and environmental influences. This ensures a longer lifespan for the product, contributing to cost savings and consumer satisfaction.

Cost-Effectiveness Compared to Traditional Manufacturing Methods

The efficiency of the TPE overmolding process, coupled with the versatility and recyclability of TPE, leads to cost-effective manufacturing. Reduced material waste and streamlined production cycles contribute to overall cost savings, making TPE overmolding an economically viable choice.

Design Flexibility and Customization Options

TPE overmolding allows for intricate and precise design features, including varying textures, colors, and surface finishes. Manufacturers have the freedom to customize products to meet specific design requirements, enabling them to stand out in a competitive market.

5. Overmolding TPE vs. Silicone

Comparison of TPE and Silicone for Overmolding Applications

Both TPE and silicone are used in overmolding due to their elastomeric properties. However, TPE offers advantages over silicone, including better processability, a wider hardness range, and superior adhesion to substrates. TPE also exhibits comparable or even superior performance characteristics in many applications.

Advantages of Using TPE over Silicone in Overmolding

TPE's ease of processing, recyclability, and cost-effectiveness make it a preferred choice over silicone for overmolding applications. TPE also offers a broader range of hardness options, allowing manufacturers to fine-tune the material properties as per the specific application needs.

Use Cases Highlighting the Superiority of TPE over Silicone

Numerous successful use cases across industries underscore the advantages of TPE over silicone in overmolding. These cases demonstrate improved product performance, longevity, and cost-efficiency when utilizing TPE, reinforcing its position as a versatile material in the overmolding realm.

6. TPE Overmolding Advantages

Improved Product Aesthetics and Tactile Feel

TPE overmolding enables the creation of visually appealing products with smooth surfaces and attractive textures. Additionally, TPE offers a pleasant tactile experience, enhancing user satisfaction and product perception.

Reduced Production Time and Increased Efficiency

The TPE overmolding process, with its rapid cooling and curing rates, significantly reduces production time compared to traditional manufacturing methods. This efficiency boost translates into higher productivity and faster product launches in competitive markets.

Environmental Benefits of Using TPE in Overmolding

TPE is recyclable and can be reused in the manufacturing process, contributing to a sustainable and eco-friendly approach. Its reusability aligns with the growing demand for environmentally responsible manufacturing practices.

7. Overmolding Design Considerations

Importance of Design in the Overmolding Process

Effective design is critical to achieving a successful overmolding process. The design of the substrate and the overmolded component must be meticulously planned to ensure proper adhesion, structural integrity, and overall functionality of the final product.

Guidelines for Designing Parts for TPE Overmolding

Designing for TPE overmolding involves optimizing wall thickness, incorporating draft angles, and selecting appropriate gating and venting locations. These design considerations are pivotal in achieving high-quality overmolded products with consistent results.

Addressing Common Design Challenges and Issues in TPE Overmolding

Common design challenges in TPE overmolding include flow marks, sink marks, and adhesion issues. Understanding and addressing these challenges through thoughtful design modifications and process adjustments is crucial for achieving the desired overmolded product quality.

8. Mold Manufacturers in India for TPE Overmolding

Overview of Prominent Mold Manufacturers Specializing in TPE Overmolding in India

India hosts several reputable mold manufacturers specializing in TPE overmolding. These manufacturers boast cutting-edge technology, vast experience, and a commitment to delivering high-quality molds aligned with industry standards and client requirements.

Factors to Consider When Choosing a Mold Manufacturer for TPE Overmolding Projects

Selecting the right mold manufacturer is pivotal for successful TPE overmolding projects. Factors such as expertise, technological capabilities, adherence to timelines, and cost-effectiveness should be carefully evaluated before engaging in a partnership.

Case Studies Showcasing Successful Collaborations with Mold Manufacturers in India

Several case studies exemplify successful collaborations between manufacturers and mold suppliers in India. These case studies shed light on how a strategic partnership with the right mold manufacturer can significantly impact the quality and efficiency of TPE overmolding projects.

9. Conclusion

In conclusion, thermoplastic elastomer (TPE) overmolding has emerged as a versatile and cost-effective manufacturing technique, offering enhanced product durability, design flexibility, and reduced production time. When compared to silicone, TPE exhibits superior processability and a broader hardness range, making it an excellent choice for a wide array of overmolding applications. Manufacturers are encouraged to consider TPE overmolding for optimal product quality, efficiency, and sustainable manufacturing practices. Understanding the intricacies of TPE overmolding and leveraging the expertise of reputable mold manufacturers can unlock a world of possibilities in product design and production.