Table of Contents:

-

Introduction to Compression Molding

-

History of Compression Molding

-

Compression Molding Process

-

Benefits of Compression Molding

-

Compression moulding products

-

Types of Compression Molding Techniques

-

Step-by-Step Compression Molding

-

Compression Molding Industry Overview

-

Dowell Moulds: Leading Compression Molding Manufacturer

-

Conclusion

1. Introduction to The Beginner's Guide to Compression Molding

Welcome to "The Beginner's Guide to Compression Molding"! This is a helpful journey into the world of one of the most versatile and impactful ways of making things. Compression molding is a powerful technique used to create a wide range of products, from car parts to things we use every day. It's special because it's really good at making things that are precise, strong, and don't cost too much.

In this guide, we'll explore the most important things you need to know about compression molding. It's made for people who are just starting to learn about it.

In this part, we'll give you a sneak peek at what's coming up in the rest of the guide. We'll learn the basics of compression molding, find out why it's been important throughout history, see how it's done step by step, learn about its advantages, and understand different techniques and how to stay safe. As we go on this journey together, be prepared to learn a lot about compression molding so you can become really good at it!

2. History of Compression Molding

Compression molding is a big deal in manufacturing, and it has a really interesting history that goes way back to the early 1900s. This way of making things changed how lots of products were created and had a huge effect on industries all around the world.

Start in Making Plastic Stuff: Compression molding first popped up in the 1930s in the world of plastics. People wanted to make a bunch of stuff really efficiently, so this method came to the rescue.

First Jobs: During World War II, compression molding became super important for making things like radio cases and insulation. These were tough items that needed to be made quickly.

Cars Get a Boost: In the 1950s, compression molding became super popular, especially for making car parts. This made it cheaper to make car stuff, and that helped the car industry grow really fast.

New Materials: As time passed, people started using different materials for compression molding. At first, they used special kinds of plastics that get hard when they're heated. But then they started using things like rubber, different plastics, and even mixes of materials.

Better Machines: Machines for compression molding got better too. They became more precise and worked better, which meant they could be used to make even more things.

All Kinds of Stuff: Because compression molding can make all sorts of shapes look great, it started being used in many industries. Think about airplanes, electronics, and things we use every day—this method has become super important.

New and fancy: Nowadays, people use computers and robots to help with compression molding. This makes everything even more perfect and wastes less material, so the stuff that's made is top-notch.

The story of compression molding is about how it went from being simple to super advanced. It changed how things are made and still changes things today. This shows how important this method is and how it keeps influencing the way we make stuff.

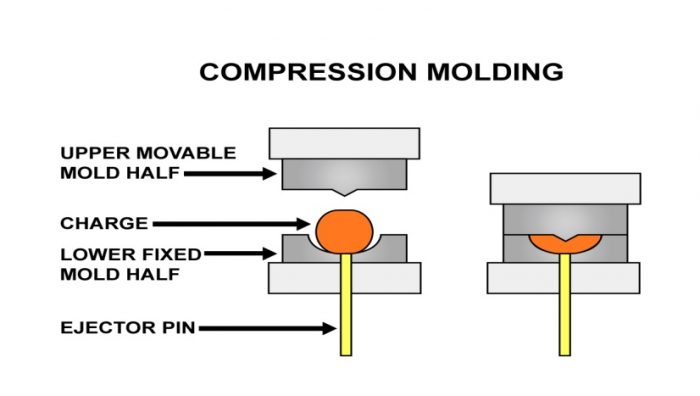

3. The Compression Molding Process

Compression molding is a clever way to make intricate parts and items for lots of different uses. This process uses heat and pressure to shape raw stuff into what we want. Here's how it works:

Choosing the Material: First, pick a good material. Usually, it's a tough kind that doesn't melt under heat or pressure, like special plastics with fiberglass.

Getting Ready: Cut the chosen material into shapes that fit the mold.

Putting in the Material: Put these shapes into a mold that usually has two parts.

Adding Heat: Close the mold and heat it up. This makes the material soft. It also makes special things inside the material start to harden it and give it the shape we want.

Squeezing it Tight: When it's hot, squeeze the mold really hard. This makes sure the material fills up the mold and takes the right shape.

Making It Strong: The heat and pressure make the material even stronger.

Cooling Down and Taking Out: After it's strong enough, cool the mold. Then open it and take out the new thing you've made.

Cleaning Up: Get rid of extra bits and make the new thing look nice.

Compression molding is great for making complex shapes and strong stuff. It's used in cars, airplanes, and things we use every day. Mixing heat, pressure, and material science makes things of super high quality.

4. Benefits of Compression Molding

Compression molding offers many benefits that make it a top choice for making things in different industries. It has special qualities that help make high-quality parts in a good way. Here are the main benefits:

Making Complicated Shapes Easily: Compression molding can make very detailed and tricky shapes easily. This is great for making all kinds of things that need different designs.

Strong Parts: The things made with this method are really strong and last a long time. This is useful for things like car and airplane parts that need to be tough.

Saves Money: Using compression molding can save money because it works with many kinds of materials and doesn't waste much. This is especially good if you're making a lot of things.

Works with Many Materials: It can be used with lots of different materials, like special plastics, rubber, and even mixed materials. This makes it good for making different things.

Precise and Always the Same: By using heat, pressure, and a good design, compression molding always produces the same good results. This means you don't need to fix things after making them.

Faster Making: It doesn't take as long to make things with compression molding compared to other ways. This helps to make more things in less time.

Good for the Earth: Compression molding is good for the environment because it uses materials well and doesn't make a lot of waste. This is important for industries that care about the Earth.

Nice Surface: The things made with compression molding look good right away. You don't need to do extra work to make them look nice.

All these good things about compression molding make it a great way to make lots of different things. It's good at making detailed and strong stuff, and it doesn't waste money or materials. This is why many companies choose it when they want to make things that are high quality and don't take too long to make.

5. Compression moulding products

Compression molding is a flexible method used to create different items for many industries. It's great for meeting different designs and needs. Here are some things that are often made using compression molding:

Car Parts: Compression molding makes tough car parts like bumpers, inside panels, engine mounts, and brake pads. These parts can handle daily use well.

Aerospace Pieces: Important aerospace parts like inside panels, seat backs, and strong parts for the structure are made using compression molding. The parts are accurate and lightweight, but still strong.

Electrical Insulators: Compression molding creates electrical insulators for things like transformers and circuit breakers. These insulators are good at not conducting electricity.

Everyday Items: Compression molding is used to make things like phone cases, housing for appliances, and kitchen tools. These items look good and are strong.

Sports Gear: Stuff like helmet shells, skateboards, and protective gear use compression molding. This makes them tough and able to handle impacts.

Medical Tools: Compression molding is used to make parts for medical devices, including things like wheelchair pieces, prosthetics, and dental products.

Tools for Industry: Handles, grips, and covers for industrial tools are often made with compression molding. This method makes them comfortable and strong.

Building Stuff: Decorative panels, tiles, and architectural parts use compression molding. This makes them strong and lets them have complex designs.

Compression molding can make a lot of different things that industries need. It's really important to make things that look good, work well, and are made efficiently.

6. Types of Compression Molding Techniques

Compression molding involves using various methods to create products according to different needs, materials, and production sizes. These methods provide flexibility in achieving specific results. Here are some of the main types of compression molding techniques:

1. Conventional Compression Molding:

This is the traditional way. It means putting the raw material into the mold and then using heat and pressure to shape and solidify it into the desired product.

2. Transfer molding:

In this method, the raw material is heated before it goes into the mold. Then it's moved into the mold, and pressure is applied. This works well for complex designs and materials that need careful control.

3. Injection Compression Molding:

This technique combines injection molding and compression molding. First, the molten material is injected into a partly open mold. Then the mold is closed to apply compression. This is good for reducing waste and getting consistent results.

4. Thermoforming Compression Molding:

Here, a heated sheet of thermoplastic material is put in the mold and then compressed. This is great for making big, light, detailed parts.

5. Sheet Molding Compound (SMC) Molding:

SMC, a mix of materials, is put into the mold before compression. This makes strong, rust-resistant parts.

6. Bulk Molding Compound (BMC) Molding:

Like SMC, BMC is a mix of materials molded under compression. It's great for tricky shapes and is often used to make parts for electronics and cars.

7. Low-Pressure Compression Molding:

This way, it uses less pressure than normal compression molding. It's good for delicate parts and materials that can change shape easily.

These different compression molding methods let manufacturers choose what suits their designs, materials, and production needs. By picking the right method for each product, manufacturers can get the best results in many industries.

7. Step-by-Step Compression Molding Process

Compression molding is a well-defined process used to make high-quality parts by using heat, pressure, and careful control. This method is known for making strong products in various shapes. Here's a simple breakdown of how compression molding works:

Getting Ready: Choose a strong material that can't be reshaped once heated, and make a basic shape out of it.

Putting in Place: Put the shape into a mold that's not closed yet. Make sure it's in the right position.

Closing the Mold: Close the mold by putting its two parts together over the shape.

Heating Up: Make the mold hot to soften the material and start making it solid.

Squishing It: At the same time, press the mold with a machine to squash the material into the right shape and get rid of any air.

Making It Solid: Because of the heat and pressure, the material starts changing and becomes solid.

Cooling Down: Let the mold cool down so the material keeps its shape and strength.

8. Compression Molding Industry Overview

The compression molding industry is really important in modern manufacturing. It makes all sorts of different things and helps make a lot of products. This way of molding things is really good because it can change to fit what's needed, and it's also really good at being efficient. Let's learn a bit more about it:

Works for Many Things: This industry helps make stuff for cars, airplanes, electronics, things people use, and more. It can make parts that are really detailed and really strong.

Saves Money: Compression molding doesn't waste materials, and it's fast, so it doesn't cost too much to make things.

Getting Better: The machines and materials used in this industry are getting better all the time. This means that things are made more exactly, with fewer mistakes, and it's easier to design new things.

Helps the Environment: This industry is trying to make less waste and use less energy, which is good for the Earth. People care about the environment like this, and it helps companies be more responsible.

All Around the World: People all over the world are part of the compression molding industry. It helps economies grow and technology get better in many places.

Learning and Making New Stuff: Smart people are always learning about new materials and better ways to mold things. They also want to do it in a way that's good for the Earth. This makes sure the industry stays really smart.

Special Things for Everyone: Because people like having things made just for them, compression molding can make things that are one-of-a-kind.

The compression molding industry keeps changing and is really good at fitting into modern manufacturing. It can be used in many ways and makes things that are just what's needed. This industry is important because it can make lots of different things, do them well, and do it in a way that's good for the Earth.

9. Dowell Moulds: Leading Compression Molding Manufacturer

Dowell Moulds is a standout player in the compression molding industry, known for its skill in creating top-notch parts for different fields. With a strong focus on new ideas and accuracy, Dowell Moulds has become a reliable maker in this field. Here's a summary of what they do:

Specialization: Dowell Moulds is a pro at making precise molds for compression molding. They serve industries like cars, planes, and electronics.

Tech Know-How: Using the latest tech and advanced techniques, Dowell Moulds makes sure its products are always great in quality and performance.

Custom Made: The company shines in making solutions that are just right. They customize molds for specific products and designs.

Quality Matters: Dowell Moulds is serious about quality. They do careful checks and tests to make sure their molds are perfect.

All Around the World: Dowell Moulds works globally. They have clients from many countries, helping lots of industries get better.

Being Creative: Dowell Moulds is always on the lookout for new stuff. They keep trying new materials, ways of doing things, and designs.

Working with Customers: Dowell Moulds loves teaming up with customers. They listen and work together to make molds that everyone loves.

Dowell Moulds is all about quality, new ideas, and making customers happy. This makes them a big name in making molded parts and helping different industries grow and move forward.

10. Conclusion

To sum up, compression molding is a key part of modern manufacturing. It's a strong method to make all sorts of different parts and products. Compression molding is really good at making things that have complex designs, are strong, and work well. It's used in lots of different industries. Here are the important points:

Works for Many Things: Compression molding is used in cars, planes, electronics, and things we use every day. It's flexible and can meet the needs of all these different industries.

Makes Strong and Durable Things: The way compression molding is done with heat, pressure, and materials helps make things that are really strong and last a long time.

Keeps Getting Better: As things change, compression molding keeps improving. The materials used and the machines used get better and more eco-friendly.

Helps Economies: Compression molding helps economies all over the world by creating jobs and new technology.

Can be Customized: People want things that are unique. Compression molding can make things that look special and work the way people want them to.

Safe and Works Well: People follow safety rules and use the best methods. This makes sure everyone is safe and things are done efficiently.

In short, compression molding is still really important because it keeps changing and solving different problems when making things. It's a big part of how things are made today.